What Is Charcoal Cube?

A. Early History

In ancient times, the production of wood charcoal in certain regions was abundant, matching the availability of tangal wood.On average, 100 parts of wood yield about 60 parts by volume or 25 parts by weight of charcoal. These stacks were covered entirely with grass or wet clay. Firing commenced at the chimney’s base, gradually spreading outward and upward.

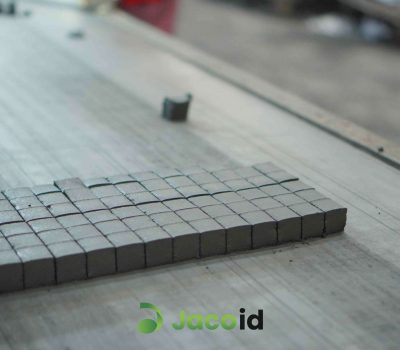

The efficiency of charcoal production relied heavily on the burning rate. Generally, 100 parts of wood yielded about 60 parts by volume or 25 parts by weight of charcoal. Small-scale operations often achieved around 50% efficiency, while large-scale methods reached up to 90%, even into the seventeenth century. The meticulous nature of this process led to the recognition of Colliers, skilled professionals in charcoal burning.

The widespread practice of large-scale charcoal production, particularly in Alpine and nearby forests, significantly contributed to deforestation in Central Europe. In Britain, people meticulously managed coppices to sustain a perpetual supply of charcoal cube by cyclically cutting and regrowing trees. Despite these efforts, people noted complaints about shortages as early as the Stuart period, attributing them to temporary yields or challenges in scaling productions to meet increasing demand.

B. Modern History

Since Brazilian law changes in 2010 aimed at reducing carbon emissions under President Lula da Silva’s initiative for “green steel,” the use of charcoal as a smelting fuel has seen a resurgence in South America.

Modern methods of carbonizing wood, whether in small batches or as sawdust in retort furnaces, are widely adopted, particularly in regions with limited wood resources. These processes not only produce charcoal but also recover valuable by-products such as wood spirit and wood tar, enhancing the overall efficiency of production.

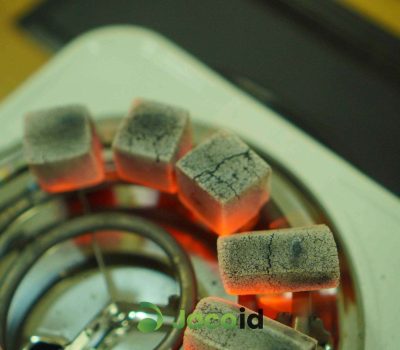

Charcoal cube generally develops at temperatures approximately 300°C (572°F), displaying a brown hue and a soft, brittle texture. At higher temperatures, it becomes more brittle but should not exceed 700°C (1292°F) to prevent the wood from turning into ash.

In Finland and Scandinavia, charcoal is often a by-product of wood tar production, with pine trees favored for their high-quality tar. This practice historically led to significant deforestation, with estimates suggesting that all Finnish forests are younger than 300 years old. The decline of tar production in the late 19th century prompted widespread reforestation efforts in the region.

Ellsworth B.A. Zwoyer of Pennsylvania originally invented and patented briquetted charcoal in 1897. The Zwoyer Fuel Company began producing it thereafter. Henry Ford later popularized briquetted charcoal by utilizing wood and sawdust, by-products of automobile fabrication, as materials. This initiative led to the establishment of Ford Charcoal, which eventually became the Kingsford Company.